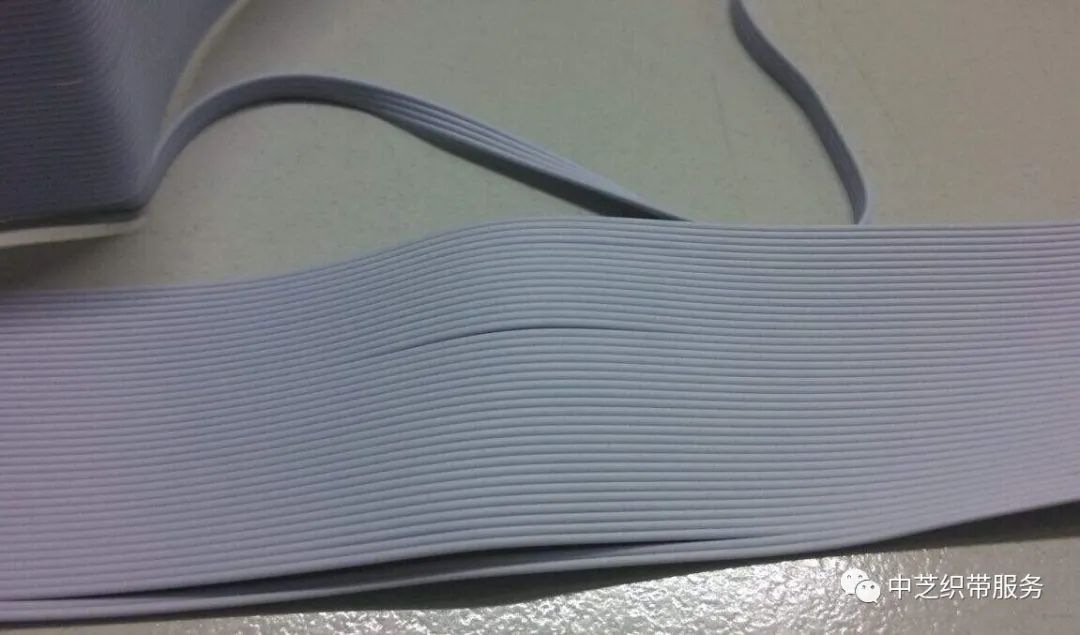

Elastic webbing needs to use to the core raw material - latex silk, hard into the capital market hardcore dry goods, the major players competing to grab the last supply market.

Latex yarn has a wide range of applications. For example, elastic fabrics used in daily life, such as various elastic bands, tight underwear, swimwear, sock gags, glove gags, belts, underwear straps, etc. Rubber patterned belt, rubber belt, elastic belt, sofa elastic belt, yarn covered silk (covered yarn), tourniquet, lining belt, industrial vulcanized rubber sheet, fitness belt, diving goggle belt, sports and fitness products, medical and health products, bandage, various elastic fabrics, non-woven products The product is suitable for high speed machine and horse weaving machine, such as flat elastic band and round rope band.

Latex yarn has a wide range of applications. For example, elastic fabrics used in daily life, such as various elastic bands, tight underwear, swimwear, sock gags, glove gags, belts, underwear straps, etc. Rubber patterned belt, rubber belt, elastic belt, sofa elastic belt, yarn covered silk (covered yarn), tourniquet, lining belt, industrial vulcanized rubber sheet, fitness belt, diving goggle belt, sports and fitness products, medical and health products, bandage, various elastic fabrics, non-woven products The product is suitable for high speed machine and horse weaving machine, such as flat elastic band and round rope band.

According to the surface treatment process is divided into "powder gluten" and "oil gluten", that is, the surface covered with a thin layer of antioxidant powder or oil, generally powder gluten is more commonly used; according to the quality level of A, B, C three levels, A grade is the best. According to the tensile strength is divided into ordinary tensile strength and strong tensile strength, strong tensile strength for sofa elastic band, elastic mattress, etc.. According to the environmental protection level is divided into ordinary grade and food safety grade, food safety grade is mainly used to fix the shape of food, the textile industry generally use ordinary grade.

The factory state is light root. 40 strips in a group, the cross-section is generally round, the color has two kinds of black and white.

Main specification models: 10#, 20#, 23#, 28#, 32#, 37#, 42#, 52#, 55#, 63#, 75#, 80#, 90#, 100#, 105#, 110#, 125#, etc. The larger the model number, the finer the rubber wire.

1, advantages: latex silk as natural rubber, its main component is cis-polyisoprene, with excellent elasticity, insulation, water barrier, plasticity, high tensile strength, good tear resistance and abrasion resistance, easy to bond with other materials and other characteristics, after appropriate treatment also has oil resistance, acid resistance, alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other valuable properties, excellent elasticity, not deformed. Therefore, it has a wide range of uses. [2]

2, disadvantages: easy to age in the air, become sticky in the heat, easy to swell and dissolve in mineral oil or gasoline, alkali resistant but not strong acid resistant.

3, aging performance: manifested as cracking, sticky, hardening, softening, chalking, discoloration, long mold, etc.. Among them in the hot air is easy to aging is the most obvious shortcomings, known as thermal oxygen aging, for example, from the finished natural rubber samples, placed in the temperature of 150 degrees aging test chamber aging a day, the observation found that aging will be easy to brittle break.

4、Shelf life of latex silk: the shelf life of latex silk is related to the refining process, generally the shelf life of the Southeast Asian side of the production in line with the storage conditions (dry, dark) lower temperature (below 20 degrees Celsius), can be saved for 6-9 months. The shelf life of Hainan gum is about 4 months. The shelf life of synthetic gum depends on the variety, ranging from 12-18 months. The key is the storage conditions. So here it is also important to pay attention to the sale of goods first in first out.

Although there are more than 2000 kinds of plants in the world can produce natural rubber, but the large-scale promotion of planting is mainly the Brazilian rubber tree. Brazilian rubber trees are native to the western region of Maranak in the Brazilian Amazon, rubber trees like high temperature, high humidity, static wind, fertile soil, mainly planted in Southeast Asia and other low-latitude areas. Now has been spread to Asia, Africa, Oceania, Latin America, more than 40 countries and regions. The countries with large planting area are: Indonesia, Thailand, Malaysia, China, India, Vietnam, Nigeria, Brazil, Sri Lanka, Liberia and so on. Due to natural conditions, China's gum planting area is mainly distributed in Hainan, Guangdong, Guangxi, Fujian, Yunnan, in addition to Taiwan can also be planted, of which Hainan is the main gum planting area, available area of about 15 million mu, planting 14 million mu or so, the annual output of about 600,000 tons.

Although there are more than 2000 kinds of plants in the world can produce natural rubber, but the large-scale promotion of planting is mainly the Brazilian rubber tree. Brazilian rubber trees are native to the western region of Maranak in the Brazilian Amazon, rubber trees like high temperature, high humidity, static wind, fertile soil, mainly planted in Southeast Asia and other low-latitude areas. Now has been spread to Asia, Africa, Oceania, Latin America, more than 40 countries and regions. The countries with large planting area are: Indonesia, Thailand, Malaysia, China, India, Vietnam, Nigeria, Brazil, Sri Lanka, Liberia and so on. Due to natural conditions, China's gum planting area is mainly distributed in Hainan, Guangdong, Guangxi, Fujian, Yunnan, in addition to Taiwan can also be planted, of which Hainan is the main gum planting area, available area of about 15 million mu, planting 14 million mu or so, the annual output of about 600,000 tons.

At present, the main high-quality latex silk supply in the market is Thailand and Malaysia, Thailand's main brands are Wilford, Fulida, Old Thailand (NRT), HV, Park Dragon, Long Tai, Flying Wheel, Crown, etc.; Malaysia's main brands are Big R, Xiwei Fei, etc.

Recently, the foreign epidemic continues to spread and is in a further development trend.

It is reported that the serious impact of the local epidemic, Malaysia originally did not return to normal port trade, was requested by the authorities to further strengthen preventive and control measures, some ports in addition to important strategic materials, all the implementation of port closure measures to ease the pressure of prevention and control brought by the epidemic.

Thailand's rubber industry is also basically in a half-open, half-shutdown state due to the local epidemic. In areas where the epidemic is more serious, the government has even asked the local community to stop rubber cutting operations to deal with the epidemic.

In this way, the domestic downstream demand manufacturers, like the elastic band factory and so on the demand side, the decline in upstream production capacity, coupled with the continued strengthening of domestic market demand, the demand gap can not be effectively supplied, the gap between supply and demand for goods is bound to become larger and larger. Directly lead the elastic band imported latex silk raw material supply is tight, holding the money waiting for the purchase of customers more and more. This caused the existing price of latex silk on the market fluctuate significantly, the recent maximum increase has reached 7,000 yuan per ton up and down, this price in the usual completely unimaginable.

Next, the development of foreign epidemic seems to become very critical, whether the latex silk industry will quickly expand production capacity to make up for the shortage of the market, or will be affected by the epidemic, continue to implement strict industrial control policies, we will wait and see.

Dongguan Kaiyuan Ribbon Co., Ltd. is a manufacturer specializing in the design and production of rope,

If you are interested, please click on this link: